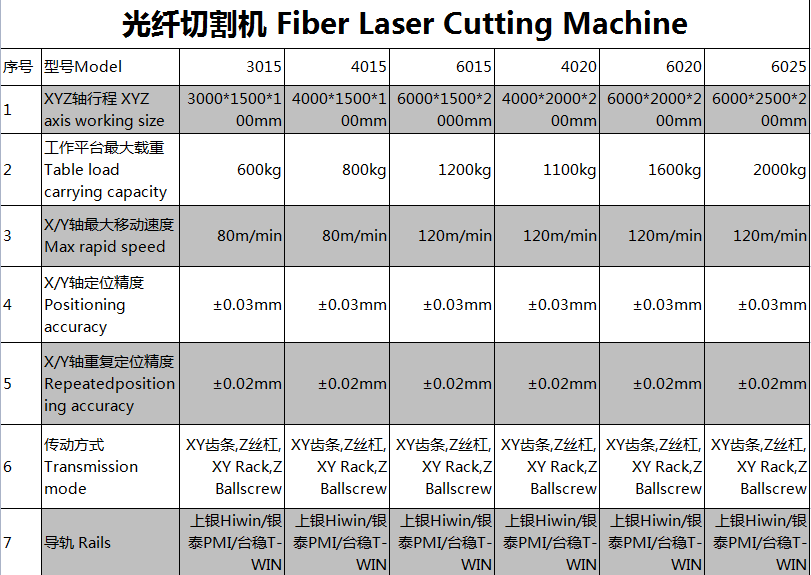

3015 Fiber laser cutting machine

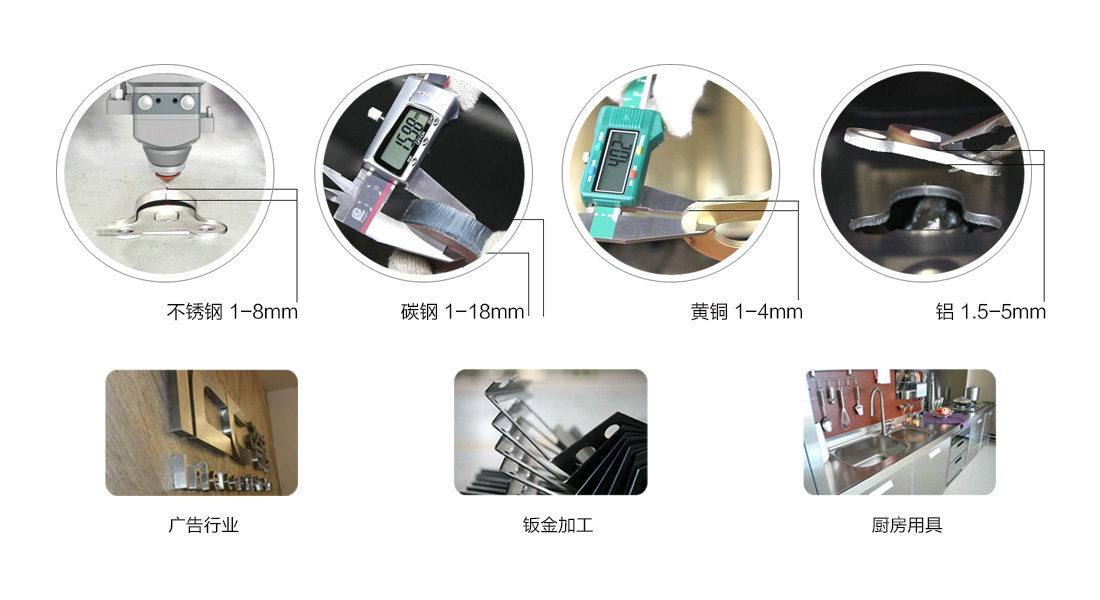

3015 Fiber laser cutting machine is used to cut flat sheet metal. for example: cabron steel, stainless steel, brass, copper, aluminum;

Fiber Laser Cutting Machine, Laser Cutting Machine, Laser Machine, Laser Cutter, Sheet Metal Laser Cutting Machine, Sheet Fiber Laser Cutting Machine, Sheet Laser Cutting Machine;

The integrated, hand-held controller allows you to store programs to its hard drive or load programs from a flash drive. It can even connect directly to you PC for file transfer and/or controller software updates.

This machine is compatible with many common CAD/CAM platforms including.If you are wanting a more in-depth overview of the design software used with machine, please contact with us and watch video on how to get started with CNC.

Increase your shop’s production with this value-packed CNC machine.

The complete and easy-to-read manual makes it easier to assemble and maintain your machine.

Like all of the computer numeric controlled machines, the machine comes with a 3-year warranty covering parts and assuring the unit is free from factory defects (Consumables are not covered by the warranty); we have 21 years Customer Service experience and professional Technical Support Teams.

Parts and accessories for the CNC machine may be available online and shipped by fedex from china.

Made in an ISO 9001 factory

CE certified

Due to product size, this item must be delivered to a loading dock or unloaded with a forklift. Liftgate not available.

Description:

This is the best fiber metal laser cutting machine,it is widely used in the advertising, craft, and decoration industry for cutting metal sheets. It can cut thin aluminum, stainless steel, carbon steel, copper, and brass sheets easily and with high precision. The control cabinet is built in the machine structure, which saves more room and is suitable for metalworkers with a small workshop.

Features:

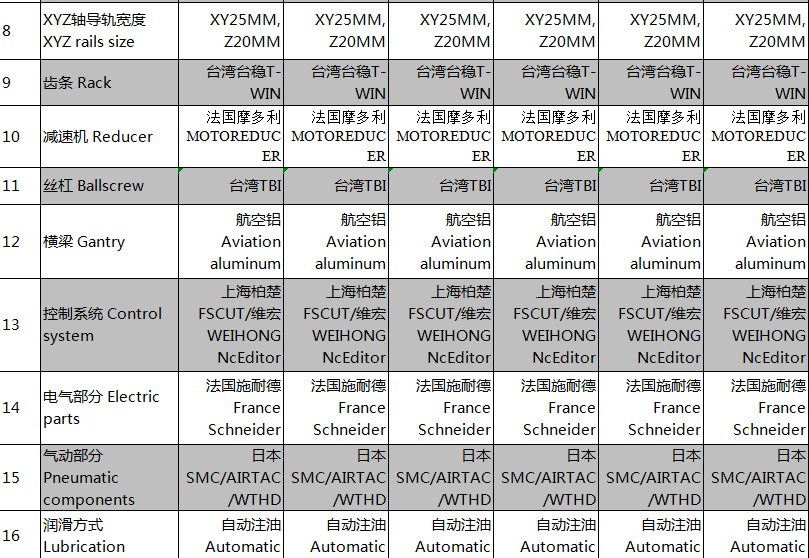

1. Intelligent automatic focusing laser head Automatic focusing mode of the laser head reduces human interference with a focusing speed of 10m/min and repeated positioning accuracy of 50um.

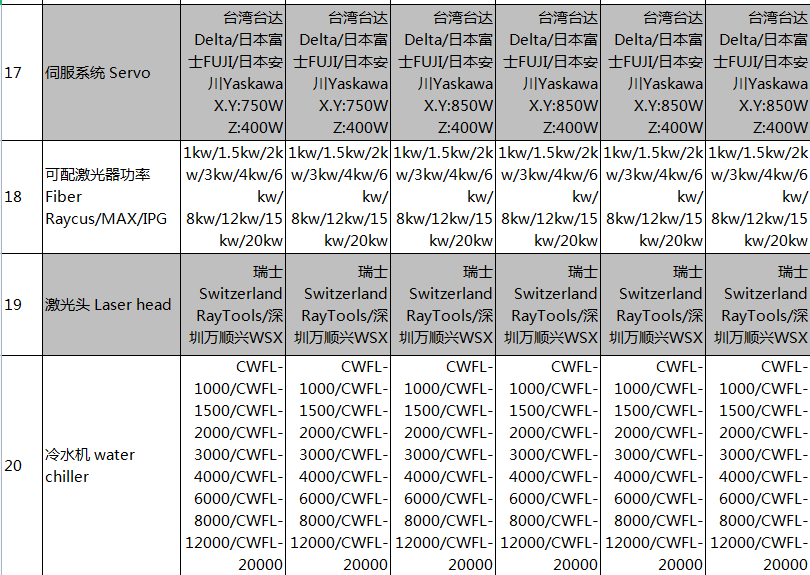

2. Staggered blade worktable The blade worktable is arranged in a staggered form, which can hold the metal sheet steadily.

3. Aircraft-grade aluminum beam Aircraft-grade aluminum is corrosion resistant, lightweight and highly rigid, guaranteeing high speed laser cutting. Besides, it also guarantee the excellent cutting precision due to the perfect dynamic performance such as anti-twisting, anti-tilting and anti-deformation.

4. Integrated large volume dust removal system The dust removal system can remove all the smoke generated from the cutting process with large air volume. This helps protect the operator’s health and the working environment.

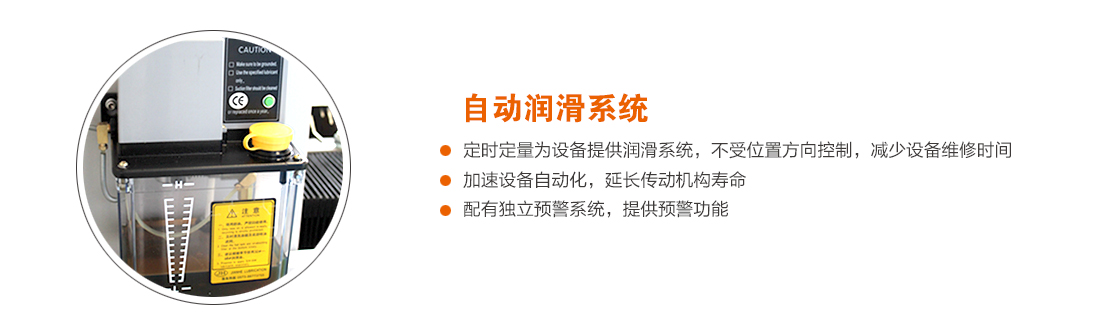

5. Automatic lubrication system Automatic lubrication method saves more human labor, reduces maintenance time, and greatly improves work efficiency.

Application:

The laser metal cutting machine is widely used to cut various metal sheet products in the advertising, craft, decoration, and other industries. It is suitable for cutting carbon steel, stainless steel, aluminum, brass, and copper parts, signs, crafts, logos, letters, etc.

Categories

Contact Us

- +86-531-88586516

- +86-531-88586517

- +86-18653142760

- [email protected]

- maxryli

- +86-18653142760

售前客服

售前客服